Clarus Aqua MkII Source Power Cable Product Description:

Aqua - Exquisite Sound Reproduction for Discriminating Audiophiles

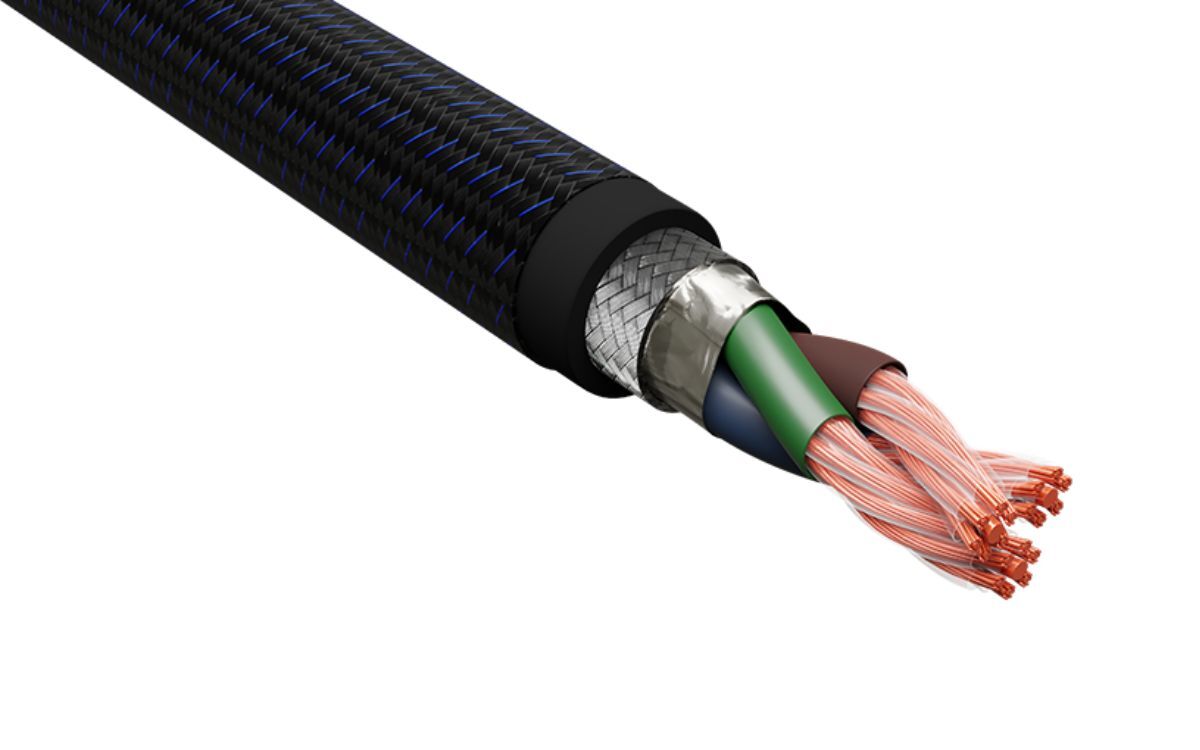

Clarus Aqua cables deliver many of the standout performance features found in the Crimson series, albeit with slightly smaller wire gauges. This reduction in size is not due to any form of scaling down but rather the result of meticulous design and evaluation by Clarus engineers. They have fine-tuned each Aqua cable to achieve peak performance from its unique topology. Similar to the Crimson cables, the Aqua series employs a multi-gauge configuration with three specially shaped and individually insulated conductors, offering exceptional bass, midrange, and high frequencies. This design ensures remarkable imaging and definition across the entire sound spectrum. The use of ultra-low-distortion PCCC conductors contributes to enhanced clarity, while the precision-formulated polyethylene (PE) insulation minimizes loss and ensures superior imaging and sound definition. The Clarus Aqua cables stand out in the audiophile market for their patented design breakthroughs and sound reproduction, much like their Crimson counterparts.

Hear More Of The Recorded Information

Clarus source power cables are specifically engineered for line-level components such as CD players, DACs, media servers, processors, and preamplifiers. These power cables are meticulously designed to minimize noise, support the low-frequency 50/60 Hz AC signal, and supply the necessary current demands of audio components without sacrificing dynamics.

Noise rejection is a critical factor in the design of these cables. Clarus uses proprietary winding techniques and triple shielding to effectively limit electromagnetic interference (EMI) from a building’s electrical grid, ensuring a low noise floor for sensitive source components. Additionally, Clarus engineers each power cable with a specialized dielectric formula and connector developed explicitly to dampen AC vibrational noise, further enhancing the clarity and purity of the audio signal.

The Purest Copper Available for the Purest Sound Possible

Clarus crafts cables for discerning audiophiles using the purest copper available. Their Pure Continuous Cast Copper (PCCC) is produced through a unique, proprietary mold extrusion process, resulting in substantial lengths of single-crystal copper. This copper is directional, free of impurities, and boasts a flexible, corrosion-resistant structure with low electrical resistance. The absence of crystal boundaries ensures structural perfection, making Clarus cables a superior choice for high-fidelity audio.

The Importance of Conductor Geometry in Power Delivery

Current capabilities in power cables are critical for maintaining optimal performance. If the wire gauge is too small, it can starve the current, but relying solely on large conductors can lead to a loss of dynamics in the audio signal. Clarus MKII power cables address this issue with a multi-gauge design that balances the need for sufficient current flow with the ability to respond quickly to transients, preserving the signal's integrity.

The use of Pure Continuous Cast Copper (PCCC) conductors, each individually insulated, ensures that the cable minimizes distortion. Clarus also employs proprietary winding techniques that further reduce signal interference. The result is a noticeable improvement in sound quality, characterized by a lower noise floor and enhanced clarity, allowing more of the recorded information to be heard.

Triple Shielding Reduces RF and EMI Noise

Clarus source power cables utilize three shielding layers to minimize RF and EMI-induced noise. This approach results in an exceptionally low noise floor that allows you to hear more of the recorded music.

Mark II – The Final Connection – Source Power Cables

Clarus Mark II source power cords are meticulously crafted with high-performance US Type B and IEC C15 connectors to ensure a secure and reliable connection. Recognizing the common issue of accidental disconnection with IEC receptacles, Clarus engineered its C15 connector with a proprietary high-retention design. This design features a raised collar on the molded end of the IEC C15 connector, providing a satisfying click when fully inserted, signaling a tight and dependable connection.

The contacts and termination pins of these connectors are made from C1100 pure copper, known for its superior electrical and thermal conductivity. Rated at 101% electrical conductivity by the International Annealed Copper Society (IACS), C1100 copper ensures exceptionally low resistance and superior sound characteristics. To prevent oxidation, the copper is gold-plated, maintaining optimal performance over time.

The connector housing is precision-machined from polymethylene (POM) and encased in a multi-layer brass and carbon fiber cover. POM offers excellent mechanical strength and vibration damping, which contribute to noise reduction, while the multi-layer shielding protects against noise interference in the AC signal. Additionally, the heavy-duty strain relief design provides robust protection, ensuring safe and long-term reliability of the power cord.